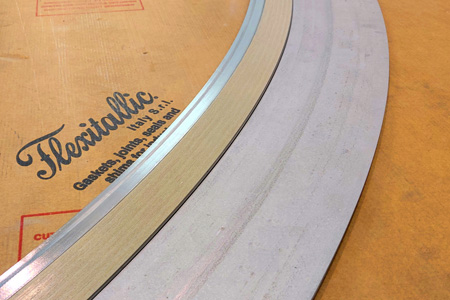

FLEXITALLIC ITALY SRL

GASKET MANUFACTURE

AND APPLICATION CONSULTING

FLEXITALLIC ITALY SRL

GASKET MANUFACTURE AND APPLICATION CONSULTING

About Us

Part of the Flexitallic Group, Flexitallic Italy with its local production and warehouse is located in Ticengo, close to the main routes in the country.

We offer special solution, consulting and engineered support across the Italy.

Manufacturing capabilities includes, Spiral Wound, Kammprofile (Flexpro), Soft Flat and Special products on drawing at request.

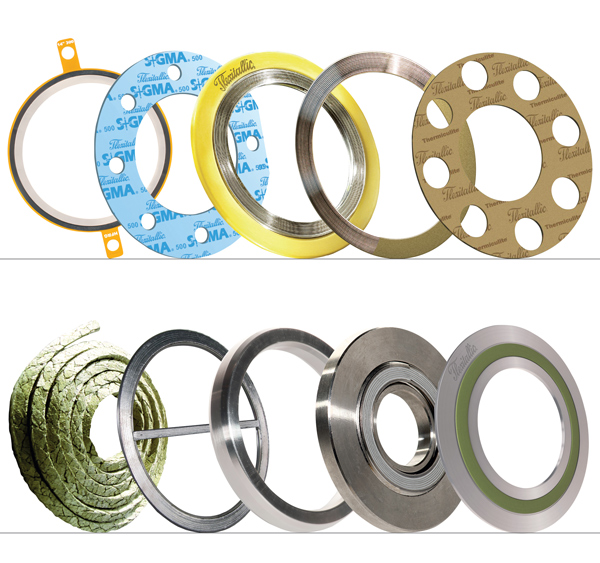

Products – Overview

With over 100 years of experience, Flexitallic are responsible for new gasket and material innovation, and are at the forefront of developing sealing solutions for industries around the world.

Flexitallic Italy offers a wide range of high quality standard gaskets and special sealing solutions that allow customers to operate in varied conditions.

These products include:

- Thermiculite®

- Change™

- Sigma® Series (biaxial modified PTFE)

- Special gasket

Thermiculite®

Thermiculite® is one of Flexitallic’s trademark products. Its versatility is the main feature: Thermiculite® can be used at high temperatures (up to 1000 ° C), in corrosive environments (eg production of acid solutions and in oxidizing environments; it also allows a longer maintenance intervals of flanged joints.

Flexitallic is able to supply different types of gaskets in Thermiculite®, Change™, Spiral Wound Gaskets, Flexpro™, packings, sheets, ISO-PRO (Insulating kit)

Typical applications:

- High operating temperatures

- Fertilizer Production

- Molten salts

- SOFC

- Fire-Safe (API 6FB)

- Packing/Valves

- Cryogenic temperatures

Change™

The thermodynamic cycles of heat exchangers are the major challenge and a serious problem for technology and conventional sealing. Flexitallic has solved this problem with the development of Change™ gasket.

The recovery of the Change™ ensures excellent sealing performance for long periods, even after countless thermal cycles.

Change™ gaskets typical applications are:

- manholes

- damaged flanges

- FCC units

- coker

- hydrogenation

- ethylene/fertilizer production and reactors

Sigma® (biaxial modified PTFE)

Using a proprietary production process SIGMA® represents the latest generation of bidirectional PTFE.

The SIGMA® series offers very high chemical resistance and is used in applications with cryogenic temperatures up to 260°C.

SIGMA® series is suitable for the food industry and in all sectors where FDA rules apply.

Sigma® 500 blue – PTFE modified with glass microspheres. It has high compressibility. It is a solution for plastic pipes or for thin and easily deformed flanges.

Sigma® 511 pink – PTFE modified with silica. It is a solution for strong acids (except hydrofluoride) and chemicals in general.

Sigma® 533 white – PTFE modified with barium sulfate. Suitable for strong alkaline and other general chemicals.

Sigma® 588 white – Sandwich PTFE, characterized by high compressibility, ideal for low load seals and damaged surfaces of the flanges. Suitable for concentrated and alkaline acid.

Sigma® 600 white – PTFE material with high compressibility and very low loads. Ideal for plastic or glass-coated pipes. Universal material suitable for a wide range of chemical media.

Sigma® 800 white – Expanded PTFE sheet material with high sealing characteristics at low stress bolt loads, and good blow-out resistance. This is the solution to most chemicals for the full pH range.

- FDA approvals, BAM

- Applications in the chemical, pharmaceutical and food industries

- Cryogenic applications

- Reactor gaskets

- Gaskets for flanges and GFK

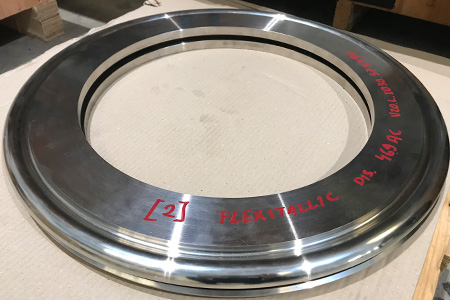

Special Gaskets

Flexitallic usually supplies special gaskets too, as:

- Weld Ring

- Double Cone

- Lens

- Diaphgram

- Norsok Ring

- Special RTJ

The design, geometries with related construction drawings, processes, intermediate and final non destructive testing are totally managed in-house.

Contact:

Flexitallic Italy S.r.l

Via Leonardo Da Vinci 6B

Ticengo CR

26020

Tel: +39 0374 71006

info@flexitallic.it